Laser induced breakdown spectroscopy

The surface analysis technique of Laser-induced Breakdown Spectroscopy (LIBS) is slowly becoming a commercial venture because of the identification of its competitive position amongst other analytical techniques.

An independent study was carried out by the Technology and Business Consultants, Robert Bogue and Partners on behalf of British Nuclear Fuels Limited (BNFL),UK to investigate the market prospects for LIBS. The study compared competitiveness of LIBS with various other techniques. The factors such as measurement precision, cost, portability and analysis time were taken into account and used to evaluate the potential of LIBS.

From this study it was concluded that LIBS would not be able to compete in situations where other technologies provide a more precise and cheaper measurement solution. Neither should an attempt be made to replace any existing technology that are well established.

LIBS has the added advantage that the analysis can be performed remotely, provided optical access can be established between the instrument and the target. When analysing a sample with other laboratory techniques the sample has to be presented to the instrument, and because of the nature of the measurement, it has to be done in a radiation free environment. This of course is not the case with LIBS because all interactions between the system and the target can be purely optical.

Therefore, LIBS has an extremely competitive position if remote, in-situ, real time analysis is required, for instance, in a high radiation (or any hostile) environment where only optical access using either an optical fibre or telescope can be used. The most appropriate applications are thus found to be those encountered in the nuclear industry where remote quantitative or qualitative analysis, without any physical contact with the sample, is preferred. This was identified by BNFL as a natural solution to some of their analytical problems where exposure of personnel to highly radioactive material is understandably undesirable.

LIBS can be used for quantitative analysis with reasonable precision. However, most remote analytical problems concern the identification of a target. In these cases the high precision measurements provided by some other techniques are not always necessary.

Lengthy Laboratory techniques with limits of detection of sub-ppb would be deemed over specified if, for example, two types of steels needed to be differentiated. The in-situ capabilities of LIBS imply that a measurement can be carried out without target manipulation, and a result is instantaneous. The sample does not have to be prepared for analysis using solvents and any surface contaminants can be ablated off the sample before carrying out a measurement. This makes LIBS ideal for metal identification problems where the target may be coated with industrial sludge or a thick oxide layer; or even submerged in liquids. Specially engineered systems can be designed and assembled for each analytical problem allowing fast decisions to be made concerning the identification of target materials which can then be immediately sorted and labelled.

There are numerous parameters in LIBS which can be adjusted and the outcome investigated. But if the setting chosen mean that LIBS can not be implemented using a fibre or telescopic system, and the target has to be in a controlled atmosphere the result is of little worth.

Thus, we would like to address the spectroscopic issues related to industrial applications of LIBS. Therefore the "arena", within which LIBS must compete, has been regarded closely. The system has to be reliable and simple to use.

The capability of LIBS also naturally lends themselves to the use for depth profiling of layered structures. This has been demonstrated with the automated depth profiling of zinc plated and galvanised steels. Additional work has also assessed the use of LIBS for the measurement of oxide thickness on aluminium samples.

As was just mentioned, the technique of LIBS will rarely be justified in an analytical laboratory because cheaper techniques often offer a better analytical solution. If sample preparation is excessive, LIBS provides a quicker but still reasonably accurate alternative to other techniques (e.g. in the analysis of ceramics which are notoriously difficult matrix materials in analysis). In remote applications the findings of these quantitative analyses are often used to just identify a material. In these situations Discriminant Analysis provides a more applicable solution. Thus by combining these pattern recognition algorithms with the engineering development of the LIBS apparatus towards telescopic and fibre systems, the potential of LIBS as a competitive analytical tool is realised.

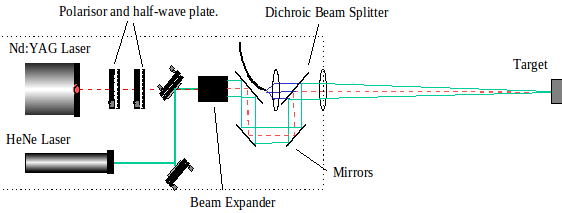

Optical Layout of Telescopic LIBS Instrument.

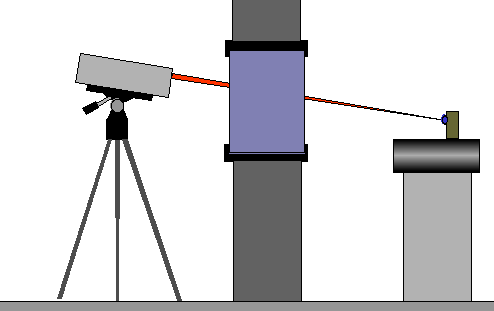

Operation of Telescopic LIBS instrument through a 1m glass shield window.

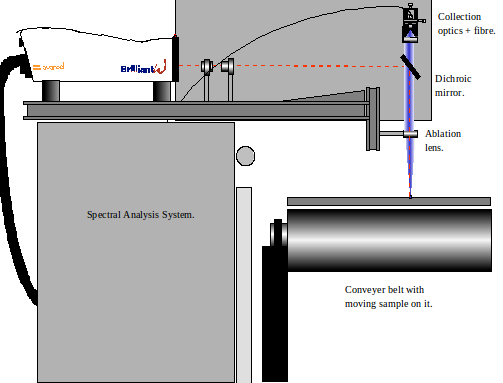

Modification of Laboratory Set-up for on-line steel analysis demonstration.

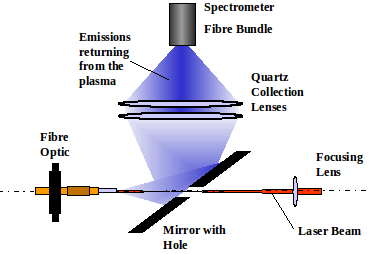

Mirror-with-Hole used to separate plasma emissions returning down the fibre with the laser radiation coupled into the fibre end.

Plan view of optical layout and experimental equipment. (Inset shows the target site arrangement.)

Theory of Laser Induced Breakdown Spectroscopy

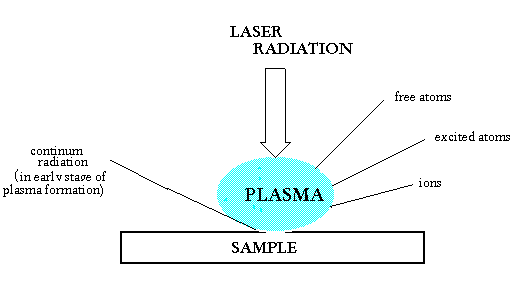

LIBS involves the formation of a luminous plasma by focusing the radiation from a pulsed fixed-frequency laser on to the surface of the sample to be analysed.

The light emitted by the hot plasma is dispersed by a spectrometer and the characteristic emission lines produced by the excited elements as the plasma cools make it possible to determine the elemental composition of the sample within the focus range. To produce the plasma there is a critical power density which needs to be overcome. This depends on the material within the focus range and follows a series: solid < fluid < gas.

The formation of a plasma due to interaction of the laser on the surface of a sample.

A few nanoseconds after the laser pulse irradiates the sample solution, a very intensive continuum emission of hot plasma is observed hence a delay between the plasma initiation and the time of observation is necessary. The delay is usually in the range of 1-2 us and after this period of time the light is collected by a fibre optic system and transmitted to the spectrometer. The collection time is known as the gate width and is usually in the range of 1-2 us.

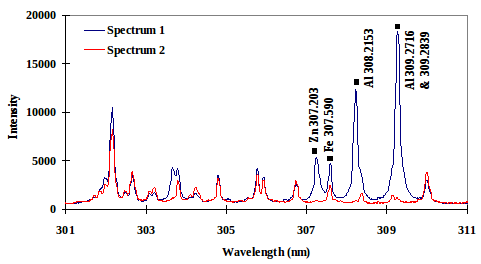

LIBS spectra showing spectral range used to analyse the coated steel samples. (Spectra taken from galvanised steel.). Spectrum 1 – surface; Spectrum 2 – substrate. The radiation from the plasma was collected via a lens-optical fibre system, and sent to a grating spectrometer. The dispersed light was detected and recorded using a computer-controlled gated, intensified diode array detector system.

Contact: Mgr.Ota Samek,Dr.

E-mail: osamek@isibrno.cz, tel: + 420 541 514 127

References

Beddows DCS., Phd Thesis, Swansea University, Wales (2000).

Samek O., Beddows DCS., Application of laser-induced breakdown spectroscopy to in situ analysis of liquid samples. Optical Engineering39 (2000), 2248-2262.

Beddows D.C.S., Samek O., Liska M., Telle H.H., Single-pulse laser-induced breakdown spectroscopy of samples submerged in water using a single-fibre light delivery system. Spectrochimica Acta B57(2002),1461-1471.

Samek O.,Beddows DCS, et al., Quantitative laser-induced breakdown spectroscopy analysis of calcified tissue samples, Spectrochimica Acta B56(2001), 865-875.

Send comments to webmaster

Last modification: 20 Apr 2010