Publication by the Leibniz Institute team with participation of UPT colleagues in the journal Micro and Nano Engineering

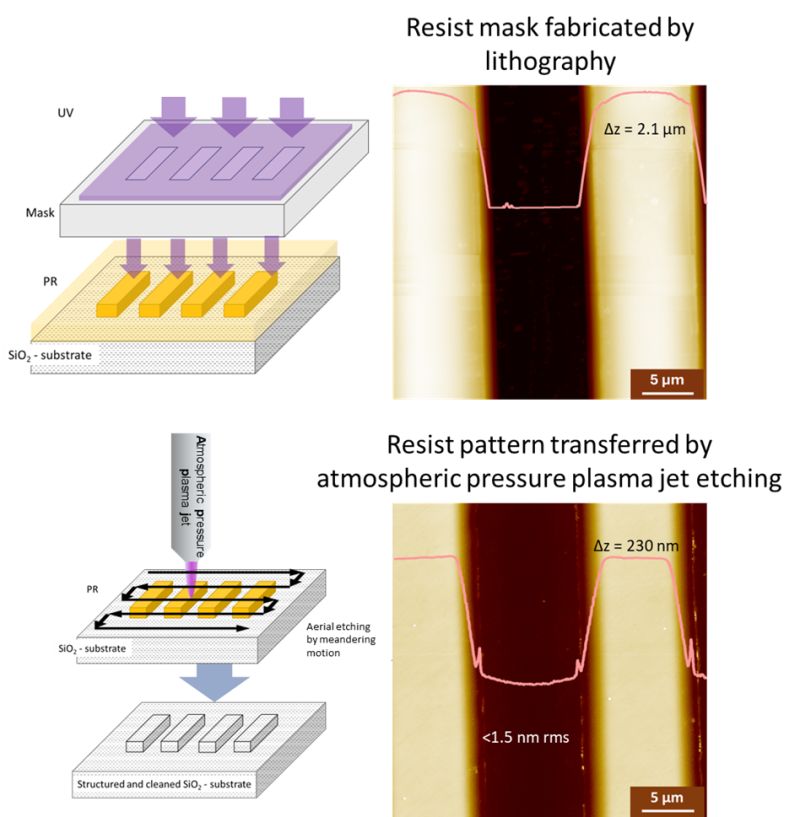

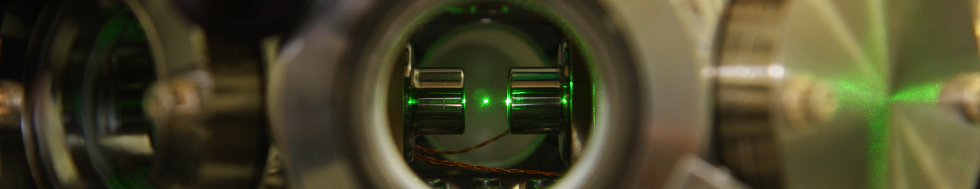

The study presents an innovative method for microstructuring optical surfaces using an atmospheric pressure plasma jet (APPJ), which enables the transfer of microstructures into quartz glass without the need for vacuum systems. This technology has the potential to significantly reduce the cost and production time of optical components while also contributing to more sustainable processing without the use of aggressive chemicals.

As part of the project, patterns from commonly available polymer masks were successfully transferred into hard materials such as quartz glass. The result was a diffraction grating with a period of 15 µm, a depth of 230 nm, and an exceptionally low surface roughness below 2 nm RMS. The study also provided important insights into etching selectivity, surface quality, and chemical changes.

This method opens new possibilities for efficient, eco-friendly, and cost-effective production of micro-optical components in the field of photonics.

Congratulations and best wishes for continued success in your future research!

Link to the publication: Stability of masking materials for pattern transfer of lithographic masks into fused silica by atmospheric pressure plasma jet etching

Authors: R. Heinke, L. Šilhan, M. Ehrhardt, P. Lorenz, J. Zajadacz, J. Bauer, T. Arnold, M. Šery, K. Zimmer

Journal: Micro and Nano Engineering, Volume 28 (2025), Article 100309

DOI: 10.1016/j.mne.2025.100309