Electron beam welding

Electron beam welding is a fusion joining method that applies an electron beam for local heating. At the point of impact, the kinetic energy of electrons, ranging from 30 to 200 keV, is transferred into heat which rapidly warms any material to its melting point. The process takes place in a high vacuum (pressure 10−2 to 10−3 Pa), most often without additional material. Thanks to very high power concentration, the focused beam penetrates rapidly into the metal, producing a deep and narrow weld. As a result of the clean, high vacuum atmosphere, even highly reactive metals like titanium or zirconium can be welded. Due to high vapor pressure at the melting temperature, some metals like Zn, Cd or Mg, cannot be welded in vacuum. Despite high acquisition costs, electron beam welders are widely used today, particularly in the nuclear, cosmic, aviation and automobile industries.

The main advantages of electron beam welding include:

- „Knife“ form of the weld with a depth to width ratio of up to 25:1, resulting in minimal deformations and thermally affected zone.

- Welding of refractory metals.

- Very deep welds: with enough power in the beam, up to 300 mm in aluminum, or 100 mm deep welds in stainless steel can be realized.

- High productivity.

- Due to high vacuum working atmosphere, the re-melted zone can be cleaner than the basic material.

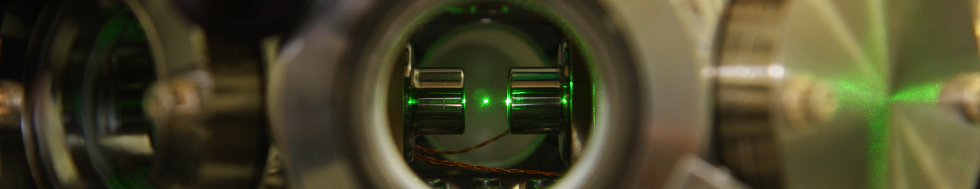

Three electron beam welders are installed at ISI Brno, all designed and manufactured in this institute. All three are equipped with cylindrical vacuum working chambers and welding manipulators for rotation and linear movement of the work-piece. The design of all three enables two positions of the electron gun on the working chamber: either horizontal or vertical. With the gun in the vertical position, the vacuum working chamber can be extended horizontally. Tubes (e.g. 5 meters long) can then be welded.

The technical parameters of these welders are:

- The oldest, but upgraded equipment ES-2 has a working chamber 600 mm in diameter and 490 mm in length. It is equipped with a 50 kV/1.5 kW electron gun.

- The “desk-top” EB welder SES-1 has a working chamber 235 mm in diameter and 165 mm in length. It is equipped with a 50 kV/1.5 kW electron gun. Five-meter zirconium tubes have been welded in the vacuum chamber when extended horizontally.

- “Experimental” electron beam welder MEBW-60/2-E with a similar working chamber is equipped with a 60 kV/2 kW electron gun. The electronic equipment of this welder is completely digitalized and computer controlled. This enables, for example, automatic, pre-programmed welding that is perfectly reproducible.

The MEBW-60/2-E welder can also be operated in a mode similar to a scanning electron microscope. In this mode the objects in the vacuum chamber can be, at a magnification of up to about 30 times, displayed on the computer monitor, e.g. to inspect the weld before venting the working chamber. The welder in this mode can also be used for the precisely localized surface heating needed for hardening or annealing of thin surface layers.

Applications of electron beam welders at ISI Brno:

- Welding high and ultra-high vacuum components (fittings, valves, etc.).

- Components for nuclear power engineering (e.g. heat exchangers).

- Joining of dissimilar materials (e.g. aluminum to titanium and/or nickel, or silver, copper to stainless steel, titanium to steel, and many other combinations).

- Welding of refractory metals such as molybdenum or tungsten.

- Welding of highly reactive metals such as like titanium or zirconium.