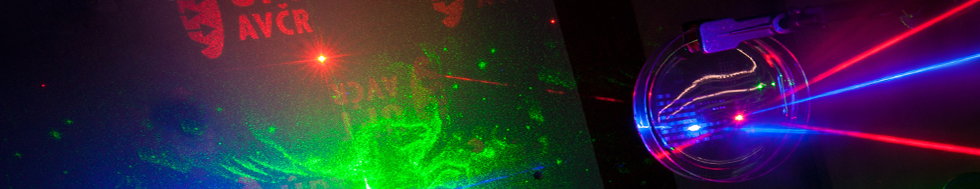

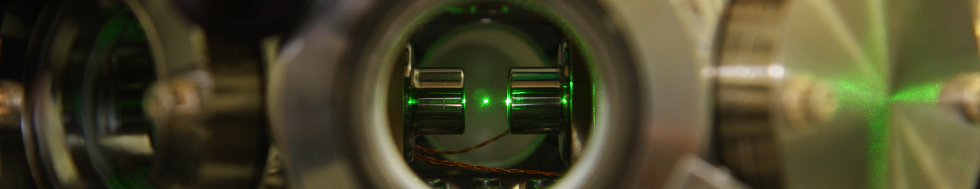

Environmental scanning electron microscopy and detection systems

The environmental scanning electron microscopy (ESEM) is a modern solution for the observation of any type of nonconductive objects without the necessity of coating with a metallic or carbon layer. In addition, wet samples of animate or inanimate origin can be preserved and observed close to their natural status.

If the gas pressure in the specimen chamber of ESEM is higher than about 200 Pa, the primary and signal electrons collide with gas molecules in the vicinity of the sample and ions generated in this way compensate for the charging of the specimen by incident electrons. If the pressure of gas, or rather water vapours, in the specimen chamber is higher than 611 Pa (at 0°C), wet objects do not dry up and remain observable in their original non-collapsed shape.

The ESEM can be used to study:

- the surface structure of conducting and non-conducting natural animate and inanimate samples;

- wet samples and samples near the phase transition (condensation, evaporation, melting, solidification, etc.);

- specimens in conditions of mechanical and thermal strain in the vacuum or in a gas of optional humidity;

- material, topographic or voltage contrast enabling one to observe electric charge accumulation and distribution e.g. on transistor gates;

- reactions of various chemical substances in the specimen chamber;

- aggressive chemical substances, e.g. battery mass;

- various types of specimens in conditions close to atmospheric pressure.

Selected applications of ESEM and research results obtained in cooperation with industrial partners:

- Study of dozens of selected materials before and after corrosion by chemical substances, specification of the resistance and lifetime of examined materials and assessment of the changes of their mechanical properties due to corrosion.

- Study of inner surfaces of several types of vascular catheters in order to assess the surface relief from the point of view of danger of the embolism.

- Study of the surface of working electrodes of electrochemical sensors oriented at mapping the surface topography structure, measurement of its real and geometric surface area and subsequent optimization of the production process and launching of a new type of electrochemical sensor.

- Study of the surface structure of solar cells to map the effects of laser beam machining on cell properties.

- In cooperation with a medical institution an extensive study has been performed on the effects of different techniques for the removal of tartar from human teeth.